¶ Introduction

An aircraft engine is the component of the propulsion system for an aircraft that generates mechanical power.

There are several types of engines: Piston and jet engines with or without propeller.

¶ Propeller

An aircraft propeller is an aerodynamic device which converts rotational energy into propulsive force creating thrust which is approximately perpendicular to its plane of rotation. The rotational energy can be produced by a piston or gas turbine engine or, in limited applications, by an electric motor.

Propellers have minimum two blades spaced evenly around the hub. They are available in fixed pitch or in variable pitch configurations, and in different design like constant speed, contra-rotating and counter-rotating types.

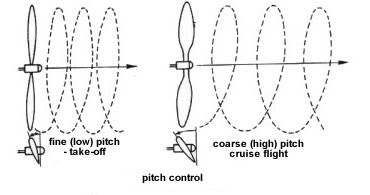

"Pitch" describes how much the blade of the propeller is twisted relative to the path it travels as it turns. This is also known as the angle of attack, and is usually measured in inches.

The cross section of a propeller is similar to a wing and is subject to the same aerodynamic issues such as angle of attack, stall, drag and transonic air flow.

Like a wing, propeller performance is degraded when it is not at its optimum angle of attack. To overcome this deficiency, many propellers use a variable pitch mechanism to adjust the blade pitch angle as the engine speed and aircraft velocity change.

¶ Fixed pitch propeller

A fixed pitch propeller is the simplest of propeller designs. It is used in many piston engine aircraft. In these installations, the propeller is mechanically linked to the engine and its rotational speed is directly related to the engine speed.

The angle of attack of a fixed pitch propeller cannot be changed during aircraft operation, it is set at installation of the engine. The blade angle is a compromise between the optimum pitch for take-off, climb and cruise.

¶ Constant Speed Propeller

A constant speed propeller is a propeller that is designed to automatically change its blade pitch to allow it to maintain a constant revolution per minute (RPM), irrespective of the amount of engine torque being produced or the airspeed or altitude at which the aircraft is flying.

It is a system which permits the pilot to select the propeller and engine speed that the pilot wants for any situation, and automatically system maintains that RPM under varying conditions of altitude, phase of flight, airspeed and power.

When the blade pitch is reduced, the torque required to spin the propeller is reduced and the airspeed and RPM of the engine will tend to increase. When the blade pitch is increased, the torque required maintaining a constant RPM increases, and the engine and the propeller will tend to slow down.

¶ Piston Engine

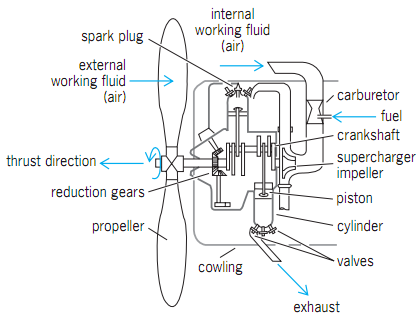

An aircraft piston engine is an internal combustion engine that uses one or more reciprocating pistons to convert pressure into a rotational motion to drive a propeller. The aircraft piston engine operates on the same principles as the engines found in most automobiles.

Most engines installed in current generation aircraft are of the horizontally opposed configuration.

However, there are examples of virtually all of the following engine types still being flown in production, experimental and vintage aircraft.

There are many types of piston engines:

- In-Line Engine (example: used in DH82 Tiger Moth): The earliest aircraft engines were of the in-line or "straight" variety and had the cylinders in a line, similar to many automotive engines.

- Rotary Engine (example: used in Sopwith Camel): They were developed during World War I for military aircraft. In this design, the entire engine rotates with the propeller, creating additional airflow for cooling.

- V-type engine (example: used in Supermarine Spitfire ):It is basically the equivalent of two in-line engines joined in a "V" configuration by a common crankshaft (The best known engine is the supercharged Rolls Royce Merlin )

- Radial Engines (example: used in B-25 Mitchell): It consists of one or more rows of odd-numbered cylinders arranged in a circle around a central crankshaft. Due to the small size of the crankcase, this engine type had a better power to weight ratio than most other designs of their day.

- Horizontally Opposed Engines (example used in Diamond DA20): They are often referred to as flat engines. They have two banks of cylinders staggered on opposite sides of a central crankcase. The design is simple, reliable and easy to maintain.

¶ Jet Engine

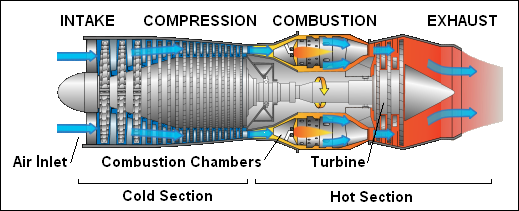

A jet engine is a reaction engine which provides propulsion by expelling a reaction mass. Most jet engines used in aviation are air breathing, axial flow, and gas turbine engines.

A gas turbine is a rotary engine that extracts energy from a flow of combustion gases:

- Ambient air is drawn into the engine intake where an axial and/or a centrifugal compressor increase both the pressure and temperature of the air before feeding it into the combustion chamber.

- In the combustion chamber, fuel is added to the hot, compressed air and ignited. Once ignition has occurred, it is self-sustaining as the constant flow of air and fuel provide for continuous combustion.

- A high energy exhaust stream, produced by burning fuel/air mixture, leaves the combustion chamber passing through one or more turbines which serve to drive the compressor(s). The remaining exhaust gas is ejected through a nozzle providing thrust (force) to propel the aircraft forward.

A jet engine is most efficient when the speed of the aircraft that it propels approximates the speed of the exhaust gas. As aircraft are designed for speeds much slower than that of typical jet exhaust, the engine turbines are also used to drive other components such as fans, propellers....

¶ Turbojet engine

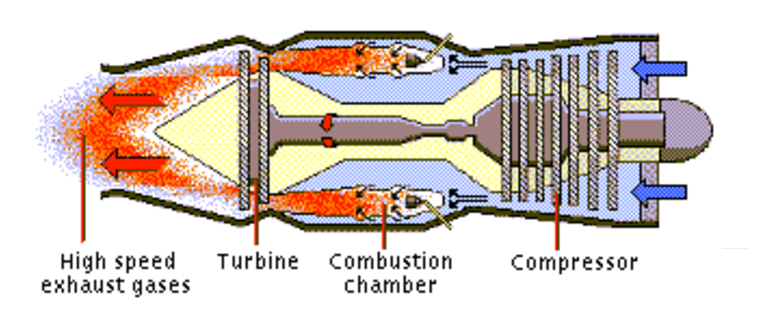

A turbojet engine is a jet engine which produces all of its thrust by ejecting a high energy gas stream from the engine exhaust nozzle. 100% of the air entering the intake of a turbojet engine goes through the engine core.

Turbojet aircraft work on the principle of accelerating a relatively small mass of air to a high speed. Turbojet engines do not reach peak efficiency until speeds approaching Mach 2. For sub-Mach speeds, a turbofan engine is more efficient and also much quieter due to the greater mass and lower speed of the exhaust stream leaving the engine.

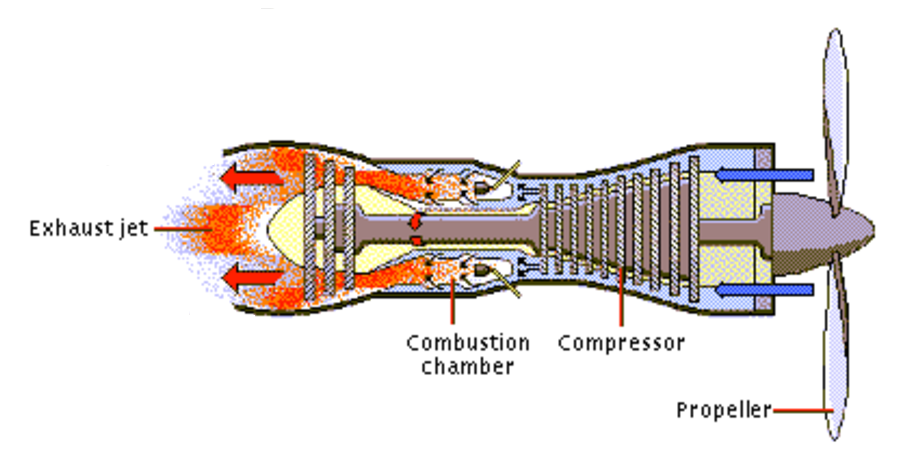

¶ Turboprop engine

A turboprop engine is a variant of a jet engine that has been optimised to drive a propeller. Turboprop equipped aircraft are very efficient at lower flight speeds burning less fuel and requiring less runway for take-off and landing than a same size turbojet or turbofan powered aircraft.

A turboprop engine uses the same principles as a turbojet to produce energy, that is, it incorporates a compressor, combustor and turbine within the gas generator of the engine. A turboprop engine is very similar to a turboshaft. Turboprop engines are mounted in following aircraft: Pilatus PC-12, Bombardier Dash 8, Alenia ATR 72...

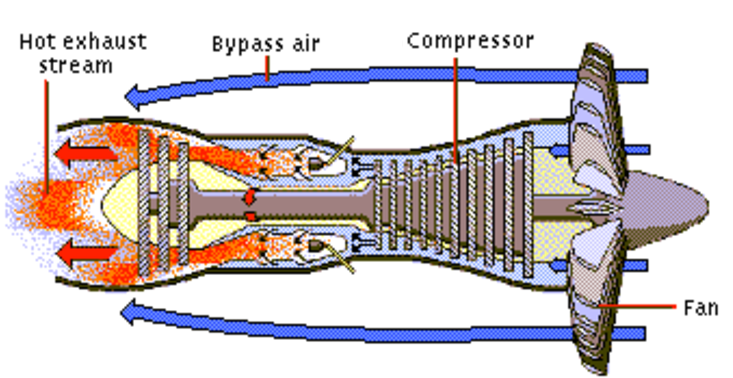

¶ Turbofan engine

A turbofan engine (or fanjet) is a jet engine which produces thrust using a combination of jet core efflux and bypass air which has been accelerated by a ducted fan that is driven by the jet core. The ratio of the mass of air bypassing the engine core versus the mass of the air going through the core is named the bypass ratio.

If a turbofan engine derives most of its thrust from the jet engine core efflux, it is a low bypass engine. If a turbofan engine derives most of its thrust from the fan, it is a high bypass engine.

Low bypass engines are most commonly found in military aircraft, and may be equipped with an afterburner. High bypass turbofan engines are the prevalent design in today's commercial aviation jet engines.

The fan airflow is accelerated by the fan and passes through the engine remaining outside of the engine core. The cold air stream moves much slower than the hot stream gas flow passing through the engine core. The cold stream serves to help cool the engine core and the hot stream, and also decrease the speed of the exhaust flow. This speed reduction serves to both reduce the noise generated by the engine and to increase the engine efficiency.

¶ Turboshaft engine

A turboshaft engine is a variant of a jet engine that has been optimised to produce shaft power to drive machinery instead of producing thrust. Turboshaft engines are most commonly used in small powerful light weight engine found in helicopters and auxiliary power units (APU).

A turboshaft engine is very similar to a turboprop. The principal difference between the two is that the turboprop version must be designed to support the loads of the attached propeller.

- None

- Airplane Flying Handbook (FAA)

- VID 150259 - Creation

- VID 256272 - Wiki Integration

- VID 496402 - Wiki.js integration