¶ Introduction

All around the world civil aviation is a part of market economy with rare exceptions. No matter who operates aircraft, large air company or small regional air club, everybody tries to reduce operation costs and therefore save money. Reality of aviation business requires a huge amount of factors to be considered on a daily basis: economics, marketing management, crew scheduling, flight operations, engineering and maintenance management, technical condition of aircraft etc. And the most effective way to take all these factors into account is to use the Cost Index (CI).

¶ CI definition

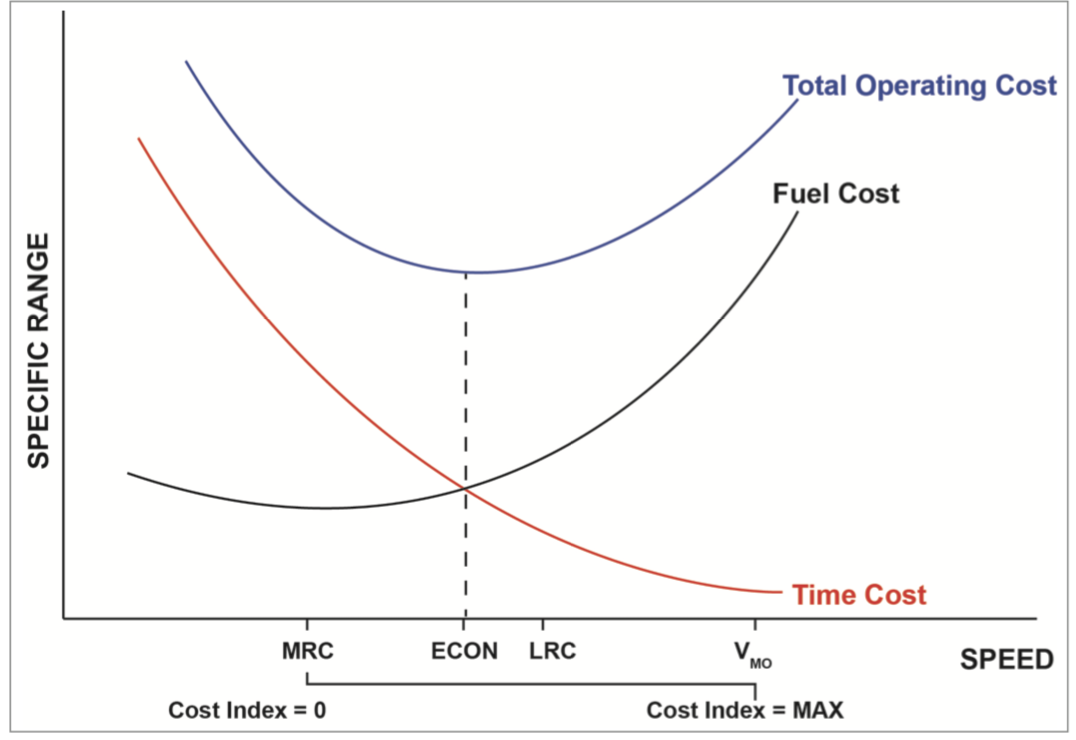

The fundamental rationale of the CI concept is to achieve minimum operation trip cost by means of a trade-off between time-related costs and fuel-related costs.

CI is used to take into account the relationship between time- and fuel-related costs.

Used appropriately, the CI feature of the flight management computer (FMC) can help airlines significantly reduce operating costs.

¶ Trip cost

Generally, the total cost of a specific trip is the sum of fixed and variable costs:

C = (CF × ΔF) + (CT × ΔT) + Cc

where:

- CF = cost of fuel per kg

- CT = time-related cost per minute of flight

- Cc = fixed costs independent of time

- ΔF = trip fuel

- ΔT = trip time

Since we can't affect the fixed cost, we need to minimize the variable cost (fuel- and time-related).

¶ Time-related costs

As an example, time-related costs contain the sum of several components:

- Hourly maintenance cost. Excluding cyclic cost.

- Flight crew and cabin crew cost per flight hour. Usually it includes crew salaries, rest cost, crew availability etc.

- Marginal depreciation or leasing costs. The cost of ownership or aircraft rental for extra flying. In practice, these costs are commonly called marginal costs : they are incurred by an extra minute or an extra hour of flight.

In addition to the above time-related costs, extra cost may arise from overtime, passenger dissatisfaction, hubbing or missed connections. These costs are airline specific.

¶ CI calculation

COST INDEX = COST OF TIME / COST OF FUEL

Therefore CI is a kind of dimensionless coefficient showing the ratio of time cost to fuel cost.

CI is used to take into account the relationship between fuel-related costs and time-related costs.

With time-related costs, the faster the aircraft is flown, the more money is saved in time costs. This is because the faster the aircraft is flown, the more miles can be flown for time-related components. It also means that more miles can be flown between inspections when considering maintenance costs.

However, if the aircraft is flown at such a high speed, the fuel burn increases and total fuel cost for the trip increases.

Adding the time-related costs and fuel-related costs together produces a total operating cost. The flight management system uses the time and fuel- related costs to help select the best speed to fly.

FMC vendors use different mathematical expressions of CI. It could be scaled from 0 to 999 or it is going from 0 to 99.

Let's take a look on two extreme cases:

- CI = 0

In this case time cost as low as zero and fuel cost is extremely sufficient (greatest influence of fuel cost in the operating bill). It is the minimum fuel mode for the best range (MRC).\ - CI = MAX

In this case fuel cost means nothing compared to the time cost. It is the MINIMUM TIME MODE for Maximum Speed (VMO/MMO)

CI effectively provides a flexible tool to control fuel burn and trip time between these two extremes. Knowledge of the airline cost structure and operating priorities is essential when aiming to optimize cost by trading increased trip fuel for reduced trip time or vice-versa.

¶ CI and ECON speed

Generally speaking, a given CI will result in a specific still air True Airspeed at altitude.

It is normal for the FMS to adjust the mach number (MN) by .01 when the head wind or tail wind components exceed a programmed threshold value: the airplane will slow down with a tail wind, speed up with a headwind (automatically) by .01 mach in an effort to minimize the fuel burn.

Looking at the figure above you can see from the total operating cost curve that the speed which gives the minimum total operating cost is the most economical speed to fly.\

This speed is called ECON, in other words the minimum cost speed.

Increasing CI from zero to maximum will increase the ECON speed from the maximum range speed to maximum operating speed.

In general at a given CI:

- the higher the flight level, the higher the ECON Mach,

- the higher the aircraft gross weight, the higher the ECON Mach.

¶ Typical cost indexes

Let's get through some typical CI examples. It will help to make flight planning more precise and accurate.

Regarding IVAO, it's clear that the CI concept is something left out of consideration. Flying online we do not pay for fuel, so time becomes the only element important for each flight. So, using the maximum CI is logically justified. But firstly we try to be as real as it gets and, secondly, it's a great fun to take all real world conditions into account.

¶ Aircraft list

(MRC = Maximum Range Cruise; LRC = Long Range Cruise)

Airbus

| Type | MRC | Typical | LRC |

|---|---|---|---|

| A32X | CI = 0 | CI = 50-80 | CI unknown |

| A330 | CI = 0 | CI = 30-60 | CI unknown |

| A340 | CI = 0 | CI = 30-60 | CI unknown |

Boeing

| Type | MRC | Typical | LRC |

|---|---|---|---|

| B737 CL | CI = 0 | CI = 10-30 | CI = 30 |

| B737 NG | CI = 0 | CI = 10-30 | CI = 35 |

| B744 | CI = 0 | CI = 25-80 | CI = 230 |

| B757 | CI = 0 | CI = 15-50 | CI = 85 |

| B767 | CI = 0 | CI = 15-50 | CI = 70 |

| B777 | CI = 0 | CI = 90-150 | CI = 18 |

McDonnell Douglas

| Type | MRC | Typical | LRC |

|---|---|---|---|

| MD80 | CI = 0 | CI = 10-50 | CI unknown |

| MD11 | CI = 0 | CI = 80-120 | CI = 200 |

¶ Conclusion

CI is a simple and effective tool when it is appropriately used by an airline. This means airlines should have a thorough knowledge of costs in order to optimize operating economics. This is the single and only purpose of CI, keeping in mind that wrong utilization or wrong calculation of it leads inevitably to cost penalties.

- None

- Airbus Flight Operations Support & Line Assistance - Getting to grips with the cost index (issue II - May 1998)

- Michael A. Burris - Cost Index Estimation by Boeing (August 2015)

- CAE Oxford ATPL book - Flight Performance and Planning

- 531824 - Creation

- 200696 - Update

- 496402 - Wiki.js integration