¶ Introduction

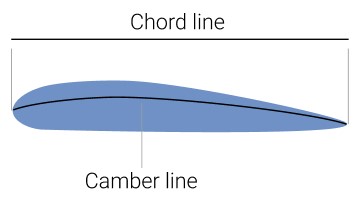

Production of lift is dependent primarily on airspeed, angle of attack and aerofoil design. A fundamental component of aerofoil design is the camber. Camber is defined as the convexity of the curve of an aerofoil from the leading edge to the trailing edge.

When your wing has a higher camber, it also has a higher lift coefficient, meaning it can produce more lift at a given angle-of-attack.

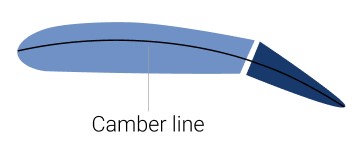

Flaps are a high lift device consisting of a hinged panel or panels mounted on the trailing edge of the wing. When extended, they increase the camber and, in most cases, the chord and surface area of the wing result in an increase of both lift and drag and a reduction of the stall speed.

¶ Function

Flaps are used during takeoff and landing phases of flight and help to improve aircraft performance.

- Flaps increase the airofoil camber, resulting in a significant increase in the coefficient of lift.

- Flaps greatly increase drag and move the center of pressure aft on the airofoil, resulting in a nose-down pitching moment. It allows you to fly a steeper descent angle to the runway.

- When used during takeoff, flaps trade runway distance for climb rate: using flaps reduces ground roll but also reduces the climb rate.

- Flaps may be fully extended for landing to give the aircraft a lower stall speed so the approach to landing can be flown more slowly, which also allows the aircraft to land in a shorter distance.

¶ Types of flaps

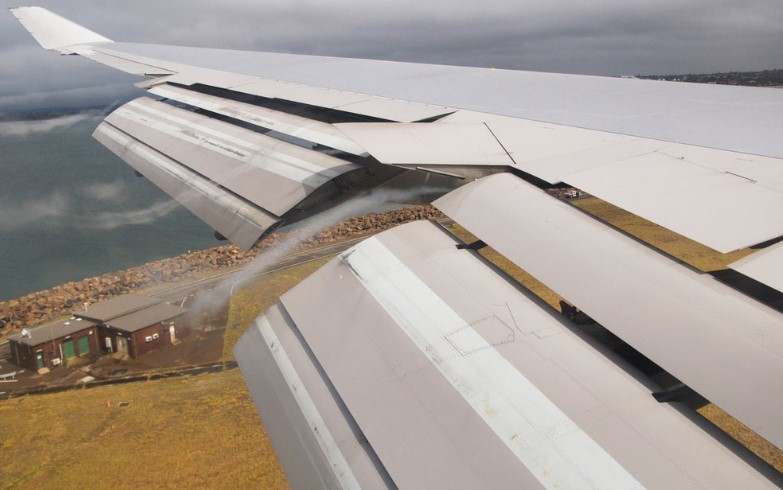

There are many different flap designs and configurations in use. Large aircraft sometimes incorporate more than one type, utilising different flap designs on the inboard and outboard sections of the wing. Let's talk about most popular configurations.

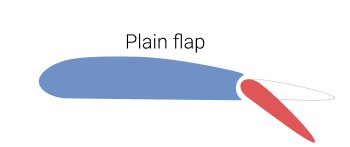

¶ Plain Flap

The rear portion of the wing aerofoil rotates downwards on a simple hinge arrangement mounted at the front of the flap. It increases the airofoil camber, resulting in a significant increase in the coefficient of lift at a given angle of attack. One of the main reasons this type of flap is not used very often is that other, more advanced flaps are now available.

Example: Cessna A185

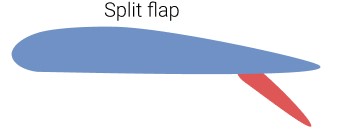

¶ Split Flap

The split flap is deflected from the lower surface of the airofoil and produces a slightly greater increase in lift than the plain flap. More drag is created because of the turbulent air pattern produced behind the airofoil. When fully extended, both plain and split flaps produce high drag with little additional lift. If you visit an airshow and look around at the older warbird planes they usually feature, you might see some split flaps. Otherwise, they are not very common these days.

Example: Douglas DC-3

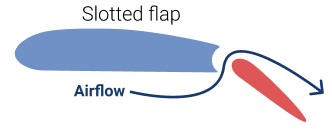

¶ Slotted flap

Similar to a plain flap but incorporates a gap between the flap and the wing to force high pressure air from below the wing over the upper surface of the flap. This helps reduce boundary layer separation and allows the airflow over the flap to remain laminar.

Slotted flap is the most popular flap on aircraft today. Variations of this design are used for small aircraft, as well as for large ones.

Example: Cessna 172

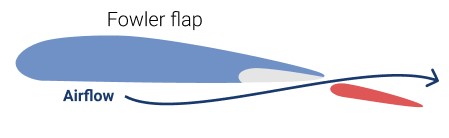

¶ Fowler Flap

A split flap that slides rearwards level for a distance prior to hinging downwards. It thereby first increases chord (and wing surface area) and then increases camber. This produces a flap which can optimise both takeoff (partial extension for optimal lift) and landing (full extension for optimal lift and drag) performance. This type of flap or one of its variations is perfect for very large jets that need a lot of lift, but a limited amount of drag.

Pilots should be aware that flap extension may cause a nose-up or down pitching moment, depending on the type of aircraft, which the pilot will need to compensate for, usually with a trim adjustment.

Example: Boeing B-52

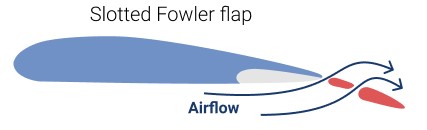

¶ Slotted Fowler flap

This design improves the performance of the fowler flap by incorporating the boundary layer energising features of the slotted flap.

Example: Boeing 747

- Pilot's Handbook of Aeronautical Knowledge by FAA - Chapter 6 Flight controls

- SKYbrary library - Flaps

- Wikipedia

- VID 531824 - Creation

- VID 496402 - Wiki.js integration