¶ Introduction

High lift devices are movable surfaces or stationary components that are designed to increase lift during some phases or conditions of flight. It is most frequently utilised during takeoff and initial climb and the approach and landing phases of flight, but may also be used in any other low speed situation. They accomplish this by increasing both the surface area and the camber of the wing. The leading edge of the airfoil can also be equipped with high lift devices.

Leading edge devices are great instruments to increase the critical angle of attack and, therefore, delay the stall.

In aerodynamics, everything comes with a penalty. In a high lift device's case, it's induced drag, capping your airplane's cruise speed and efficiency. That is why on modern aircraft it is only used during certain phases of flight.

¶ Common types

The most common types of leading edge high lift devices are fixed slots, movable slats, leading edge flaps and cuffs.

¶ Fixed slots

Fixed slots direct airflow to the upper wing surface and delay airflow separation at higher angles of attack. The slot does not increase the wing camber, but allows a higher maximum lift because the stall is delayed until the wing reaches a greater angle of attack.

A good example of an aircraft which uses fixed slots is the Zenith CH750, light utility airplane.

¶ Movable slats

Movable slats consist of leading edge segments that move on tracks. It can be either automatic, or powered and controlled by a pilot.

¶ Automatic slats

They open and close aerodynamically. When air approaches the leading edge of an airfoil, it divides; some flowing over

the top of the wing and some flowing over the bottom. The spot where the airflow splits is called the "stagnation point".

When the airfoil is at a low angle of attack, the stagnation point is on the leading edge.

When the airfoil is at a high angle of attack, the stagnation point moves below the leading edge and behind the slat. Air flowing up and over the wing pushes the slat open.

For example, a German Bf-109 fighter uses automatic flaps.

¶ Powered slats

They appear on many large aircraft and provide the same benefits as an automatic slat. However, they are electrically

or hydraulically powered - increasing reliability. The flight crew sets the slat position via cockpit controls.

For example, this is how powered slats look like on a Boeing 737.

¶ Leading edge flaps

Leading edge flaps, like trailing edge flaps, are used to increase both the lift coefficient and the camber of the wing. This type of leading edge device is frequently used in conjunction with trailing edge flaps and can reduce the nose-down pitching movement produced by the latter.

As is true with trailing edge flaps, a small increment of leading edge flaps increases lift to a much greater extent than drag. As flaps are extended, drag increases at a greater rate than lift.

As an example, leading edge flaps on the wing root of a B737-200.

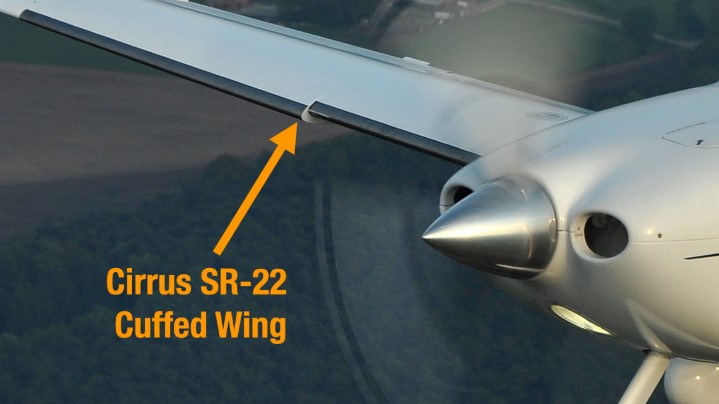

¶ Cuffs

Leading edge cuffs, like leading edge flaps and trailing edge flaps, are used to increase both CL-MAX and the camber of the wings. Unlike leading edge flaps and trailing edge flaps, leading edge cuffs are fixed aerodynamic devices. In most cases, leading edge cuffs extend the leading edge down and forward. This causes the airflow to attach better to the uppersurface of the wing at higher angles of attack, thus lowering an aircraft's stall speed. The fixed nature of leading edge cuffs extracts a penalty in maximum cruise airspeed, but recent advances in design and technology have reduced this penalty.

The best modern example of cuffs is used on the Cirrus SR-20/22.

- Pilot's Handbook of Aeronautical Knowledge by FAA - Chapter 6 Flight controls

- SKYbrary library - High lift devices

- boldmethod.com

- VID 531824 - Creation

- VID 496402 - Wiki.js integration