The engine monitoring is done by two means: a command that we operate, and a driving parameter that is checked.

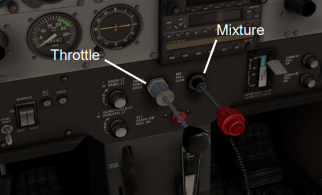

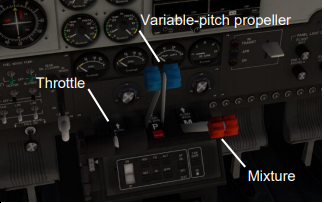

The driving of the engine is not the same if it is fixed-pitch propeller or variable-pitch propeller. Another chapter will deal with these different systems. However, the use of the mixture control is identical for the two types of propellers. The various controls used to operate the engine are color coded:

- red for mixture control,

- black for throttle control,

- yellow or grey for carburetor heat control,

- blue for variable-pitch propeller control (if this command is present).

¶ Function

The carburetor is calibrated to atmospheric pressure at sea level with mixture control set in the full rich position. As the aircraft climbs in altitude, the density of the air in the carburetor decreases, but without adjustment of the mixture the amount of fuel remains the same. Poor management of the mixture can lead to certain problems and malfunctions. This is why it is important to correct the air fuel mixture during all phases of flight; take-off, climb, cruise, descent, landing and go-around. The correction of the mixture is done via the mixture control (rich or lean).

The chemically perfect mixture corresponds to about 1 gram of gasoline for 15 grams of air (i.e. 7%).

Since the process of adjusting the mixture can vary from one aircraft to another, it is important to refer to the airplane flight manual.

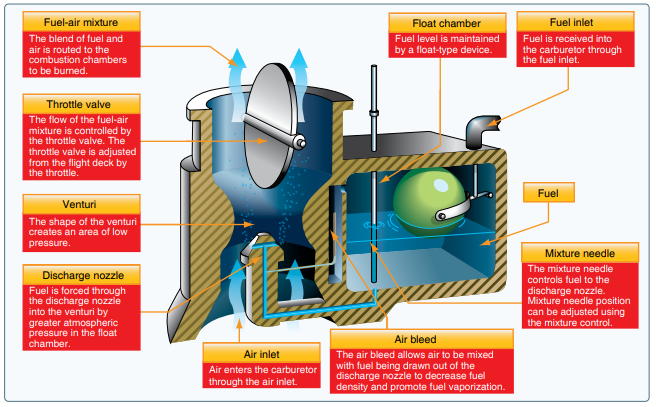

There are two categories of carburetors: float-type carburetors and pressure-type carburetors. Pressure carburetors are not generally found on general aviation aircraft. The difference between these two types is the way the gasoline is distributed.

As shown in the diagram below, the mixture needle controls the amount of fuel going to the discharge nozzle. The mixture needle is adjusted by the mixture control. The air-fuel mixture is produced by the venture effect upstream of the carburetor throttle valve.

During the take-off, climb, landing and go-around phases, the mixture control should be set to full rich. This fuel ratio is calculated so that the air-fuel mixture gives the engine maximum power.

The best way to maintain the proper fuel-air mixture is to monitor the exhaust gas temperature (EGT), or engine RPM indicator. During the cruise, above a certain altitude (see your flight manual), usually 4000ft, the reduction of the mixture is recommended.

However, if you are on a mountain airfield (or in very warm areas), the mixture setting should not be full rich, refer to the flight manual.

¶ Mixture Management

The mixture command is used to adjust the amount of gasoline in the air-fuel mixture to ensure proper combustion. Remember:

- a lean mixture favors the overheating of the engine and the appearance of detonation phenomena,

- a rich mixture leads to high consumption and clogging of the engine.

¶ FIXED-PITCH PROPELLER

To get the best power, and therefore the right mixture (in cruise phase), you can proceed this way:

- slowly deplete the mixture,

- note a slight drop in the engine RPM indicator,

- enrich the mixture to maintain the best engine RPM,

- monitor the temperature of cylinders.

¶ VARIABLE-PITCH PROPELLER

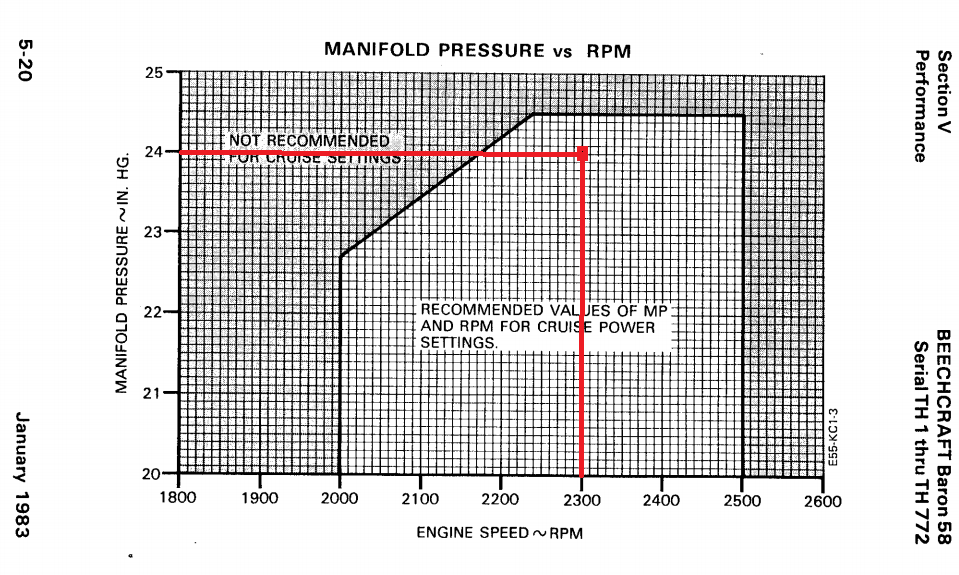

Aircraft with a variable-pitch propeller are generally equipped with a fuel flow indicator. The fuel flow corresponds to the maximum engine power, and the most economical mixture (see manufacturer's instructions - performance chapter). To maintain a perfect air-fuel mixture while cruising, the mixture must be impoverished by means of the mixture control. The impoverish of the mixture decreases the fuel flow, which compensates for the decrease of air density. In this manual (see example below), a table indicates according to the engine RPM, the manifold pressure to be adjusted.

So, we can use any combination of MP and RPM, as long as values stay within the table's area called RECOMMENDED VALUES OF MP AND RPM FOR CRUISE POWER SETTINGS; for example 2300 rpm at 24 in.Hg.

¶ EGT System

The EGT indicator (Exhaust Gas Temperature) measures the exhaust gas temperature of the least well-cooled cylinders. The temperature of the exhaust gas varies according to the air-fuel mixture entering in the cylinders. The EGT indication can be used to correctly regulate the air-fuel mixture via the mixture control.

Technique for reducing EGT with a mixture control (economical consumption):

- impoverish the mixture,

- keep the mixture lean so that the needle is stable,

- gradually increase the mixture to reach the lowest temperature.

In any case, you must follow the method in your flight manual.

¶ FADEC System

Some general aviation aircraft are equipped with an engine control system, FADEC (Full Authority Digital Engine Control).

The FADEC system is composed of a digital computer, called EEC (Electronic Engine Controller), or ECU (Engine Control Unit) and ancillary components. This system automatically regulates the engine/mixture (fuel injection system). The regulation of the pitch propeller is also automated.

The gain of consumption is between 15% and 20% depending on the aircraft compared to a conventional system.

- Pilot's Handbook of Aeronautical Knowledge -- Chapter 7 -- Aircraft Systems

- Aircraft Pilot's Manual -- Cépaduès Edition -- Chapter 1 -- Driving the engine

- SKYbrary library -- Flight Technical

- VID 529524 - Creation

- VID 496402 - Wiki.js integration